Manufacturing ERP is designed to to increase the revenue and accelerate growth of the company by providing better control over cost inventory management , improving functionality and productivity and enhancing visibility. A manufacturing ERP can create scope of expansion for the companies and give a guideline to the future. Here we are going to discuss the importance of ERP software in the manufacturing sector.

Manufacturing Enterprise resource planning (ERP) is a software system that helps you run your entire business, supporting automation and processes in finance, human resources, manufacturing, supply chain, services, procurement, and warehouse tracking systems to stay alert on the stock and orders.

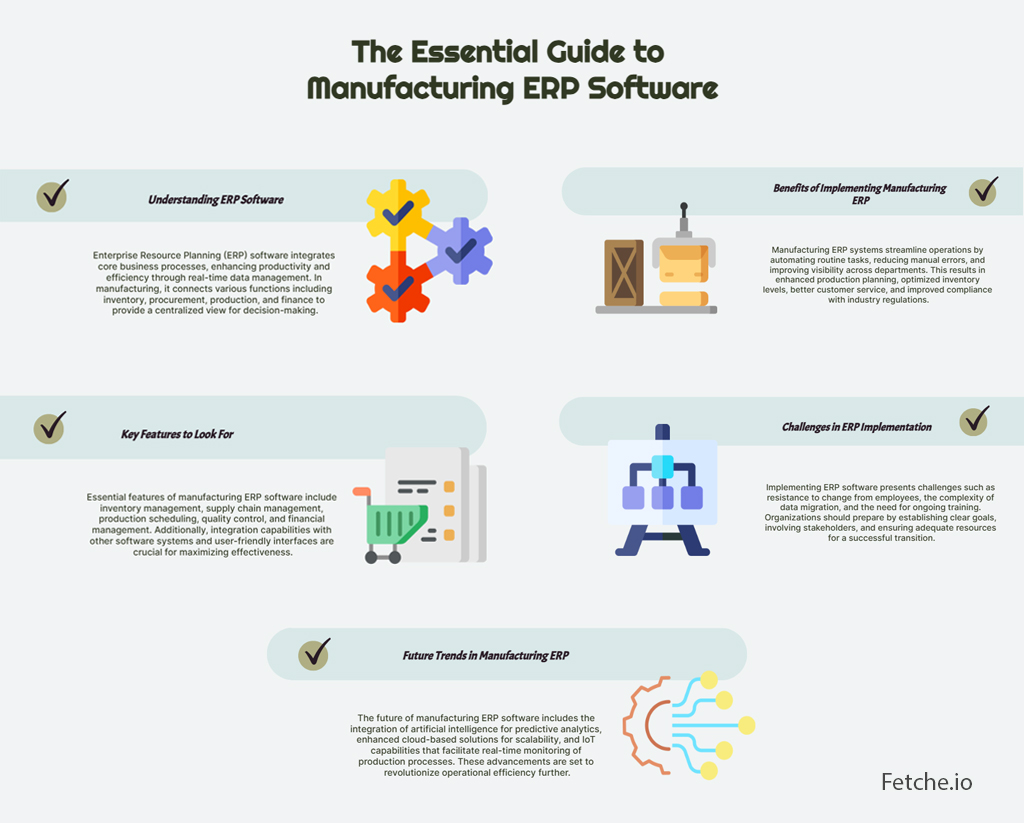

Importance of manufacturing ERP

Manufacturing software is vital in modern business; an ERP system customized to serve its purpose is indispensable for any manufacturer. Optimizing and simplifying the production process is essential to reducing human effort. Let’s look at the reasons why a manufacturing ERP is so inevitable.

Enhanced Efficiency

Streamlined operations: Repetitive and mechanical works can be done more efficiently without hurting the process and utilize the resources efficiently.

Optimization

Optimization is key. By leveraging ERP Software, embracing technological advancements, establishing SOPs, and providing comprehensive training, businesses can significantly reduce the likelihood of errors. When optimizing the work, companies can use the resources better and reduce the cost.

Increased productivity

Process optimization will always bring instant changes in productivity. Manufacturing ERP software is a key to multiplying the capabilities of the production unit.

Manufacturing ERP’s role in decision making

Better information: Accurate information about inventory status, production details and order details.

Data-Driven Insights: With ERP software in the system, it is easy to obtain accurate information that will enhance decision-making.

Better Forecasting: Helps predict the future with accurate data and read the progress instantly.

What are the must-have features required for manufacturing ERP software?

Production planning and Scheduling

Production planning is essential for manufacturing ERP software, as operations depend on it. The Master Production Schedule (MPS) and Material Requirements Planning (MRP) are crucial for optimizing manufacturing, reducing the cost of production and flawless supply of materials.

Inventory Management

Inventory management is crucial for maintaining optimal stock levels and preventing overstocking and scarcity. The inventory tracking system must be included in freight forwarding and manufacturing ERP software for flawless operation. ERP for warehouses is another ERP that comes under these sectors. A warehouse tracking system must be included in the inventory management sector for better inventory insights.

Quality Control

Product quality is crucial for customer satisfaction and business growth. Consistent quality can only be achieved if the ERP software is manufactured with a leading-edge quality assessment system.

Supply Chain Management

Effective supply chain management is essential for the timely delivery of products and raw materials. An efficient supply management, purchasing, and order system, along with a robust freight management system, can significantly reduce errors and delays in the supply chain. By utilizing manufacturing ERP software, companies can gain a competitive edge through precise supply chain management. Supply chain management ERPs normally will have a module similar to ERP for warehouses. Warehouse tracking systems enable the supply chain can avoid dispatch delays and improve customer satisfaction.

Financial Management

Financial management is crucial for sustaining a manufacturing business. Ledger accounts, accounts payable, and receivables must together provide actual insights into the financials, enabling effective decision-making processes.

Customer Relationship Management (CRM)

Effective customer relationship defines the growth of any manufacturing business taking the feedback from the customers and acting on their complaints is a must. A bad experience for a customer can hurt the whole brand itself. Manufacturing ERP software must have a customer relationship to help the active communication channels and analyze the customer responses.

Types of softwares for manufacturing

There are many softwares which directly connects to the manufacturing industry but the industry itself is so vast so the companies often customize their software for manufacturing to align with their core business.

Enterprise Resource Planning: ERP software connects different departments of the business, such as finance, HR, manufacturing, and supply chain, into a single software. The centralized system improves the efficiency and accountability of the business and its operations. Integrating platforms like Logistics ERP Software in Singapore further strengthens coordination between logistics and core business functions, ensuring smoother end-to-end process management.

Product Lifecycle Management (PLM): PLM software manages the entire lifecycle of a product, from design and development to manufacturing, distribution, and retirement. It helps streamline product development processes, improve collaboration, and ensure product quality.

PLM: PLM, AKA Product Lifecycle Management, manages the entire cycle of the products from the design to delivery. It can help businesses understand the entire development process, improve collaboration and ensure product quality, and insights can lead to better performance.

Enterprise Asset Management (EAM): An enterprise asset management system is something made to manage the assets of the company. It can tell the depreciation, repair cost, replacements and everything about a company’s assets.

Overall Equipment Effectiveness (OEE): OEE software measures the overall effectiveness of manufacturing equipment. It helps identify areas for improvement, such as reducing downtime and increasing production output.

Transportation Management System (TMS): TMS software optimizes transportation and logistics operations. It helps manage carrier relationships, plan routes, track shipments, and reduce transportation costs.

Things To Check When Choosing a Manufacturing ERP Vendor

While evaluating a manufacturing ERP software, the following considerations play key roles: Scarcity to accommodate growing futures; the ability to have an adaptation of the customized form in accordance with business demands; integration capabilities of a chosen system with all established existing ones; cloud and premises deployments; user-friendly approach; reporting and analytical modules for the system, great support and training programs with customer service; secured means for sensitive data handling and protecting against potential threats, being a cost-effective process and inexpensive in terms of both licenses and implementation procedures. Manufacturing ERP software must have a warehouse tracking system to complement the sales and production.

What ERP Solutions for Manufacturing Does FETCHE Offer?

Fetche is an excellent ERP software designed specifically for the warehouse, manufacturing and logistics industry. It offers a one-stop solution for small businesses by providing a single system that can serve as ERP software for warehouses, manufacturing ERP systems, and manufacturing software for small businesses. It is an end-to-end ERP channel that simplifies operations, documentation, record-keeping , tracking, and analysis. Fetche’s warehouse tracking system is one of its kind which has a proven track record of serving multinational shipping companies.

If anybody is looking for ERP Software for the warehouses, fetche can be the right stop. It has all the inventory management and record-keeping modules, which will enhance the warehouse’s optimization. ERP software designed for warehouses is usually not customizable, but fetche is an exception here; it can be customized as per the requirements of the business.

For the manufacturing industry, fetche is a blessing. It can automate the documentation, inventory and vendor management, accounting, tracking and analysis, which makes the process easier and helps the resources to be occupied in super valued works.

FAQ

Manufacturing ERP software connects all core business functions—production, inventory, purchasing, finance, and sales—into one system. It helps companies plan resources better, track materials, and manage daily operations without using multiple disconnected tools.

ERP reduces manual paperwork, automates repetitive tasks, and provides real-time data from the shop floor. This allows teams to plan production accurately, avoid delays, and minimize material wastage.

It is useful for small, medium, and large manufacturers who struggle with stock mismatches, production delays, or lack of visibility between departments. Growing businesses benefit the most as operations become more complex.

Yes. Many ERP systems include modules for shipment planning, warehouse tracking, and supplier coordination. Businesses that also use Logistics Management Software in Philippines can integrate it with ERP to get full visibility from production to delivery.

Companies usually see better inventory control, faster order processing, improved product quality, and clearer financial reporting. Decision-making becomes easier because all data is stored in one place.

Look for a system that matches your industry process, is easy to customize, supports cloud access, and integrates with existing tools like Logistics ERP Software in Singapore. Vendor support and long-term scalability are also important factors.