Supply chain management is often like arranging a set of building blocks. It involves many interconnected steps, one deeply entwined with the other. A small disruption in any of it could deeply affect the other as well, causing a chain reaction that might possibly impact the entire operation. Let’s say a delay occurs in transporting shipments to the warehouse or to the port; this could potentially hold up the next step, and then the next and the next, causing delays further down the line.

In supply chain management, all stakeholders—starting from warehouse managers to customs agents—all need to be coordinated, making no room for complications and animosity. Just like a puzzle, every piece must fit together in order for the process to run smoothly. When all the parts start to align and work together pretty efficiently, the supply chain will begin to flow seamlessly. And when supply chains function smoothly, you could bring about an ROI that’s enviable. On the other hand, any inefficiencies are sure to cause delays, increased operational expenses, and customer dissatisfaction, all of which are detrimental to the performance as well as the reputation of a company.

How do ERP systems help run the supply chain smoothly?

Enterprise Resource Planning (ERP) software systems are computer programs that are designed with the motto to consolidate multiple business functions onto a single platform. ERP systems assist with managing anything from finance, human resources, and supply chain functions, among others. The main function an ERP system performs is centralizing data and automating processes in any environment or system, allowing businesses to simplify operations, facilitate communication, and base their decisions on stronger information acquired through data analysis. Enterprise resource planning integration in supply chain management enables easier monitoring of inventory, processing of orders, production planning, and other principal activities while curbing manual intervention and minimizing error.

Identifying Key Supply Chain Challenges

- High Operational Costs

Companies that typically use manual processes or stand-alone software systems for each supply chain function may end up having multiple mistakes, increased labor costs, and a headache at every end of the process. Inventory management, order processing, and shipment tracking may all become costly and time-consuming tasks if attempted without automation.

- Coordination and Communication Issues

With multiple departments working independently with no system to oversee or coordinate the process, it’s so easy for information to get misplaced or simply delayed. Without a platform to centrally pass data between departments or coordinate the operation, there are chances of mishandled orders, delayed deliveries, and misplaced inventories.

- Inventory Management

Inventory tracking is a herculean task, and undertaking it between various systems or manually can lead to multiple recurring errors. If there is no real-time information regarding inventory, where and when are the shipments placed? Companies might not be able to transport shipments on time. And this all together defeats the purpose of “delivering goods on time,” which for most cargo and logistics companies is the unique selling point.

- Limited Supply Chain Visibility

Without an end-to-end system, companies have limited visibility of their supply chain. Without integrated data and real-time tracking, it is not easy to keep track of shipment, order, or inventory progress. This invisibility makes it challenging to anticipate issues that could eventually arise due to any unforecasted reasons.

How does ERP address supply chain challenges?

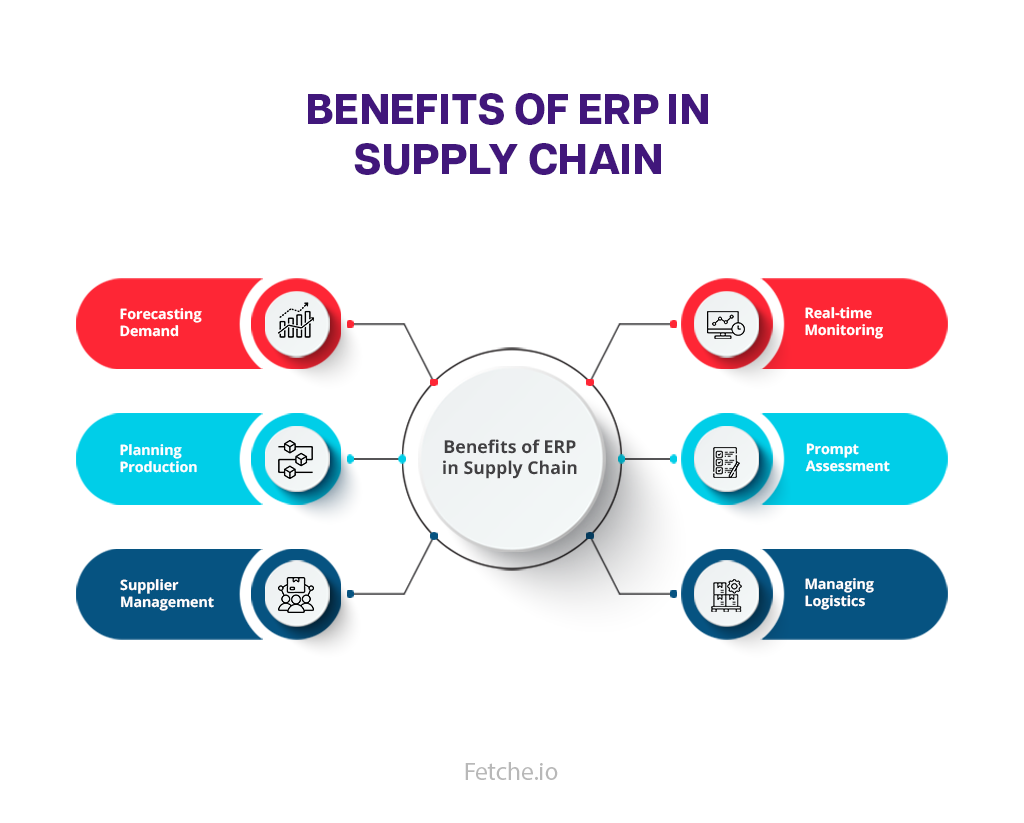

The purpose of having an ERP system for your supply chain is basically to provide a centralized, integrated solution to all or most of the supply chain management challenges. Here’s how ERP systems solve common supply chain hurdles:

- Cost Reduction Through Automation: Supply chain ERP systems mechanize numerous manual procedures that could be the sole reason for mismanagement, errors and delays, including inventory monitoring, order management, and billing. Logistics automation tools eliminate these in no time and completely rule out the need for human intervention.

- Real-Time Monitoring and Performance Tracking: If you want to track your supply chain activities in real-time through dashboards, integrate an ERP system that best suits the purpose. This integrated system helps you consolidate up-to-date information on production, shipping, inventory, and sales without having to run around or smoke your heads.

- Efficient Inventory and Warehouse Management: ERP systems include advanced tools for managing inventory. This means businesses can track stock levels, when they have come in, when they are to be shipped, and where to be shipped, etc. A warehouse management ERP/WMS ERP helps optimize storage space, improve picking and packing efficiency, and reduce operational costs.

- Better Collaboration Across Departments: Supply chain ERP systems can facilitate communication between different departments (like sales, production, and procurement), even if they are working from different locations or at the same location but through different systems.

Functionalities of ERP in supply Chain and logistics Management

- Real-Time Order Tracking

Supply chain ERP software provides real-time tracking of customer orders, from production through to delivery. With a system that enables consistently updating order status, businesses can monitor progress through every stage and notify customers about the status of their orders.

- Order Fulfillment Solutions

Supply chain ERP systems streamline order fulfillment by managing the entire process from order entry to shipment. They ensure that orders are processed accurately, inventory is updated in real time, and customers receive their products on time.

- Real-time Inventory Tracking and Forecasting

Supply chain ERP systems help businesses track inventory levels in real-time, giving managers complete visibility over their inventory across various warehouse units. ERP software also leverages historical data, seasonal trends, and demand forecasting and planning to predict future demand.

- Warehouse Management System (WMS) Integration

ERP systems integrate seamlessly with warehouse management systems (WMS), automating key warehouse tasks like inventory control, order picking, packing, and shipping. This integration ensures better coordination between warehouses and other parts of the supply chain and improves the speed of processing.

- Transportation and Logistics Optimization

Supply chain ERP software enables businesses to optimize transportation management by analyzing various factors such as delivery time, distance, cost, and available carriers. Using data, ERP can help businesses select the best shipping routes and carriers, minimizing fuel costs and delays.

- Real-Time Reporting and Analytics

Supply chain ERP systems provide detailed, real-time reporting and analytics, allowing businesses to monitor their entire supply chain at a glance. ERP helps measure key performance indicators (KPIs), such as order fulfillment time, inventory turnover, and supplier performance to identify areas of improvement and to make the supply chain a data-driven supply chain.

- Supplier relationship management

The goal of Supplier Relationship Management ERP is to build strong, mutually beneficial relationships with suppliers to improve efficiency, reduce costs, as well as drive innovation. When you open up a way for strategic partnerships with suppliers, you are ensuring timely deliveries for better pricing.

Implementation Strategies for Effective ERP Adoption

1. Setting clear-cut objectives on what your system needs is the first thing you ought to figure out before building an ERP for your system.

2. The next would be to involve key stakeholders from different departments in the discussion—such as finance, sales, procurement, and logistics—to make sure to build a system that addresses and ticks off all their pain points.

3. Next would be to choose an ERP that aligns best with your interests, and for that, you need to religiously consider the factors mentioned below:

- Ease of Use: An ERP in supply chain management should have user-friendly interfaces. If the system is complex, it will lead to inefficiencies and frustration among users.

- Cost: Consider the total cost of ownership. Opting for a cloud-based ERP solution can offer predictable expenditures and avoid expensive on-premise system maintenance.

- Ease of Integration: Check whether the ERP in question can easily integrate with existing tools and technologies.

4. The next step would be to clean up and standardize the data before data migration. Make sure you have a well-defined data migration plan, including thorough testing and validation.

5. Next would be to provide adequate training to users so they understand how the system works and how it integrates with their daily tasks.

6. Once the ERP system is up and running, it’s important to continually evaluate its performance through regular monitoring.

Future Trends and Innovations in ERP for Supply Chain Management

ERP in supply chain management will be increasingly intelligent, adaptive, and integrated in the future as they are now, with the only difference being that they will be more so than now. Among the most important trends to take over the industry, apart from digital transformation in logistics, will be the extensive use of artificial intelligence (AI) and machine learning (ML) to predict demand, route optimization, and support decision-making by analyzing vast amounts of data and IoT for supply chain visibility. Cloud-based ERP systems likewise will continue to dominate the supply chain operations, giving companies much more flexibility, scalability, and data access from anywhere. All these technologies pave the way for developing the next generation of supply chain management software that would be quicker, more reliable, and responsive to real-time inputs.

Final Thoughts

To sum up, ERP systems are the way to go if you genuinely want to improve and update your supply chain management. The best ERP system for supply chain management can streamline processes such as inventory management, order fulfillment, procurement, and production planning and control, helping companies to reduce costs, improve customer satisfaction, and increase responsiveness to market changes and all that you could ask for. With the ability to automate routine tasks, analyze data in real time, and thereby optimize workflows, ERP in supply chain management will help reap a good ROI for your business in no time.