Since the logistics industry is often referred to as the backbone of global trade, it’s no surprise that automation in logistics pretty much changed the way businesses operate around the globe. With the increasing demand for transporting goods as online businesses grow day by day, the demand for fast delivery is rising as never before. However, with warehouse management systems simplifying inventory tracking to AI in logistics optimizing delivery routes, logistics companies are also stepping up their game. And just like that, automation is reducing human error, cutting costs, and accelerating operational processes, unlike the old manual days.

Technologies like Robotic Process Automation (RPA), Internet of Things (IoT) Sensors, and Blockchain are on their way to change traditional logistics practices, which will further allow real-time data analysis, predictive maintenance, and transparent transactions, all set to immensely transform the face of logistics to keep up with the new AI-generated digital world.

Automation nowadays isn’t about staying competitive, at least not anymore—it’s about creating agile, future-ready operations that can adapt to the growing demands of global commerce. As customer expectations are way more faster and unrealistic than the actual deliverables, automation has become an investment that is quintessential to any business.

If you are on the path to full automation or are still lingering behind, this is the right spot to get started. This article will give you an outline of what automation in logistics looks like, its many benefits, the challenges you might face, and how it will shape the future of your operations.

The Growing Importance of Automation in Logistics

Logistics today isn’t what it used to be. Manual processes and siloed systems are being replaced by integrated solutions such as logistics management software or ERP software for warehouses. Businesses need agility and precision to meet the demands of modern supply chains, and automation is the key.

Benefits of Automation in Logistics

1. Eliminating Costly Errors

The biggest plus point in bringing automation to logistics is that it considerably reduces human errors. Tools like logistics management software or ERP software fully integrate inventory management systems, creating a single source of truth for data. Repetitive tasks like data entry, fuel charge calculations, and shipping documentation can be automated so as to eliminate errors caused by manual input.

2. Real-Time Freight Rates and Transport Options

Since automation provides businesses with instant access to freight rates and carrier options, companies can compare costs, insurance terms, and transit times across multiple carriers in real-time.

3. Enhanced Customer Service and Transparency

With the help of logistics tracking software and automated notifications, businesses can offer real-time shipment updates to customers, building trust and credibility. Invoice generation, transaction tracking, and supply chain monitoring when automated, make service far more accurate, and leave your customers happy.

4. Data-Driven Decision Making

Access to real-time data is a cornerstone of logistics automation solutions. Automated systems process and consolidate massive amounts of data, offering actionable insights at the click of a button.

5. Better Organizational Control and Scalability

Automation makes it all the more easier to keep track of logistics operations. Tools like warehouse management systems or ERP software, help businesses to easily monitor inventory, track assets, and manage financial transactions. As companies grow further along the way, these automated systems can scale up smoothly to handle more shipments and new users without much difficulty or any add-ons.

6. Increased Speed and Efficiency

Smart inventory systems and streamlined workflows can handle larger order volumes without hindering accuracy. Tedious tasks like order processing and shipment scheduling are done in a fraction of the time it would otherwise take to complete such dreary tasks. Needless to mention, this will let you build faster turnovers in the shortest time, and hence more profit.

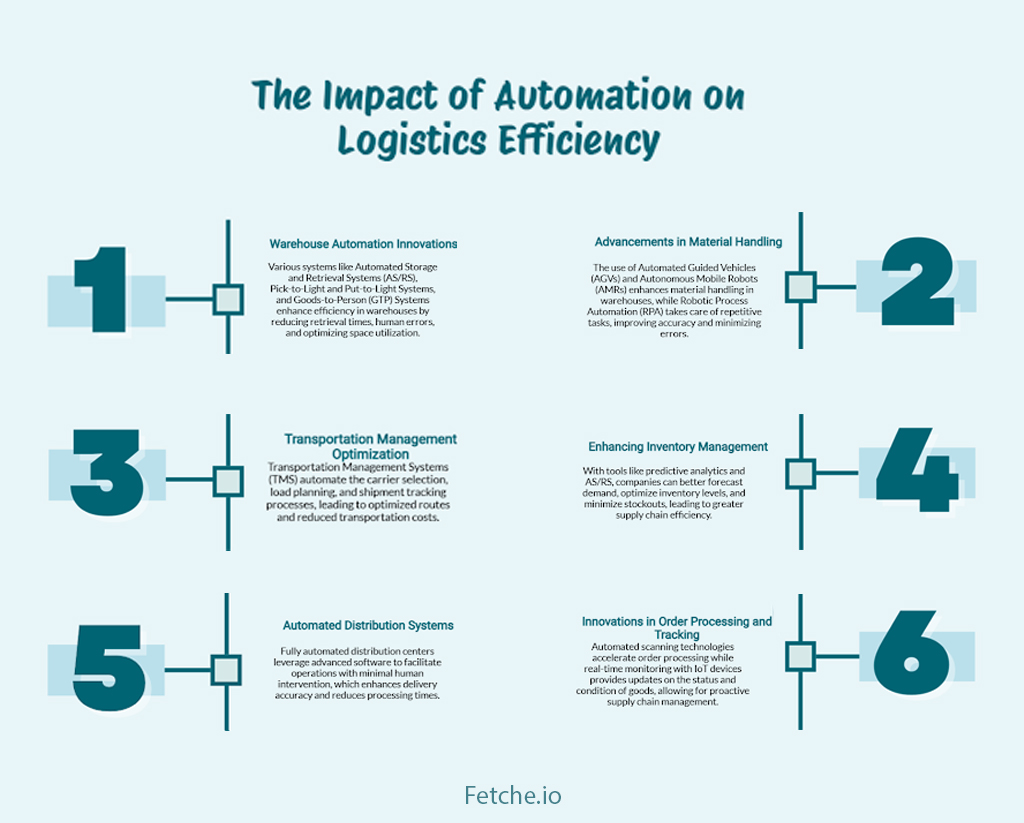

Key Areas of Automation in Logistics

- Warehouse Management: Let’s face it—managing a warehouse is no easy task. With ERP software for Warehouse and clever tools like robotic pickers and automated conveyors, businesses can streamline tedious tasks like receiving, sorting, and shipping. Warehouse automation thus, not only does cut down on common manmade mistakes but also frees up your team to focus on the bigger picture.

- Order Processing and Fulfillment: Nobody likes waiting forever for an order to arrive, and automation ensures they won’t have to. From the moment an order is placed to when it’s being shipped, automation tools can handle the process like clockwork. With Robotic Process Automation (RPA) syncing data across systems in real-time, delays and errors are either completely nil or are kept to a minimum.

- Inventory Tracking and Management: Keeping track of inventory could be a layman’s task when ERP software is implemented. Automation tools like RFID tags and smart packaging also give you real-time updates on stock levels and even help predict demand. Overstocking or running out of products would no longer be your biggest issue anymore.

- Transportation and Delivery Optimization: We all know transportation eats up a big chunk of the logistics budget, but automation can trim those costs. AI-powered tools find the smartest routes, saving time and fuel. Plus, with cool tech like drones and autonomous vehicles making deliveries, the last mile is getting faster, cheaper, and way more efficient.

- Predictive Maintenance: Ever had equipment break down at the worst possible time? Predictive maintenance makes sure that doesn’t happen. By using IoT sensors and AI, businesses can keep an eye on their machines and spot issues before they cause downtime. It’s like having a mechanic who’s always a step ahead.

- Collaboration Across the Supply Chain: Getting everyone on the same page in a supply chain isn’t always easy, but Supply chain optimization makes it simpler. With tools like blockchain and cloud-based systems, you can securely share real-time data with manufacturers, retailers, and carriers to enable supply chain optimization.

Challenges to Automation in Logistics

- High Initial Costs: Sure, automation can be a big investment upfront—things like robotics, AI, and logistics tools don’t come cheap. But think of it as planting seeds; the long-term savings in time, money, and headaches make it totally worth it.

- Employee Resistance and Skill Gaps: Let’s be honest—change is hard. Some employees might worry about losing their jobs or feel unsure about using new tech. That’s why it’s so important to communicate how automation can help them, not replace them. Plus, with the right training, your team will feel confident and ready to take on the future.

- Data Security Risks: With all the sensitive information automated systems handle, security has to be a top priority. Hackers are always lurking, so investing in encryption, access controls, and regular updates is non-negotiable. It’s like locking your front door—you don’t want to leave things wide open.

- Infrastructure Limitations: Automation can’t work its magic without solid internet and modern infrastructure. If you’re dealing with spotty connectivity or outdated setups, that’s a hurdle you’ll need to overcome. Building the right foundation—stable networks and reliable power—will make all the difference.

Future Trends in Logistics Automation

The logistics industry is in its booming era, driven by the rise of online businesses and the growing influence of social media. Here are some of the future trends that will shape logistics in the near future:

1. Autonomous Vehicles and Drones

While full autonomy in trucks and drones is a matter of discussion for another few years or so, we’ll see increased pilot programs and gradual implementation, particularly in controlled environments. Drones may become more common for small parcel deliveries in urban areas.

2. Robotics in Warehouses

Robotics in logistics will handle repetitive tasks like sorting and packing which could sound a little ajar but totally attainable, while humans could focus on decision-making and more complex tasks. Automated guided vehicles (AGVs) and robotic arms could improve warehouse efficiency, but again will only remain in discussion panels for another few years or so.

3. Blockchain for Transparency

Blockchain will gain traction shortly for tracking shipments and ensuring data integrity across various supply chains. It will primarily be used in industries that are very much in need of traceability, like pharmaceuticals and food, to reduce fraud.

4. Real-Time Data Analytics

The use of real-time data will go on to increase considerably, for businesses to integrate predictive analytics to optimize routes, monitor inventory, and improve maintenance schedules.

5. IoT for Enhanced Connectivity

IoT sensors will be more commonly used, for real-time tracking of goods, equipment, and vehicles. Companies will be able to use IoT for predictive maintenance in order to ensure supply chain optimization.

These trends, while not revolutionary overnight, will slowly transform logistics in the years to come.

Why Automation is Essential for Future Growth?

Automation is set to completely transform the logistics industry, solving big challenges like the demand for faster deliveries, labor shortages, and rising operational costs. With the eCommerce world growing faster than ever, customers now expect speedy, efficient service—and that’s where automation comes in. By streamlining workflows, cutting down on errors, and speeding up processes, Automation will push logistics companies to stay competitive while scaling to meet the demands of a rapidly growing market. It also tackles the labor crunch by taking over repetitive and physically exhausting tasks, giving employees the chance to focus on higher-value, more strategic work.

The businesses that invest in logistics automation solutions today will lead tomorrow.

Conclusion: The Time to Automate is Now

The logistics industry is changing fast, and the businesses that adapt now will lead the way tomorrow. It hardly matters if you’re just starting with automation or looking to take your existing systems to the next level, you can take a look at Fetche, an ERP software, built specifically for freight and cargo companies, to help streamline operations, optimize resources, and future-proof your business.

Ready to take the next step and bring digital transformation in supply chain? Reach out to us today to explore how Fetche’s customized ERP solutions can transform your supply chain.