Logistics is a complex sector. Even the smallest errors can be very costly and there are a lot of factors to keep track of. For instance, timely deliveries, cost control, and customer satisfaction are all important. The sector is further complicated by tight margins.

The current situation is trickier than ever with a rise in customer expectations. However, there is still a reliable way to cut costs and maximize ROI. And that is automation. Automated logistics systems have transformed businesses worldwide. Manual tasks have been automated and labor costs have been cut. However, logistics automation is known for its initial investment. Are the final returns truly worth it? That is the question we are going to try and answer here. Keep reading.

Logistics Automation

You might already know what logistics automation means. But let us just explain it to avoid any confusion later. Logistics automation is the use of software and machinery to make logistics tasks simpler and more efficient. ‘Efficiency’ is the key here. We are not just delegating human tasks to machines. We are making the machines do things better. For example, your workforce might be able to plan out delivery routes manually. But route optimization software can do the same task more efficiently. They take less time and they are less prone to errors.

Some other examples of logistics automation are warehouse automation, order fulfillment automation, and transportation management systems (TMS).

You might already be planning to invest in an automation system. The question now is ‘Which one should you invest in?’. To make that decision consider these pointers:

- Ask yourself, what your business needs are. What are the pain points of your customers? Which processes in your business need improvement?

- Once you have an answer to those questions, you can choose a system that suits your needs. Maybe what your business needs is warehouse management software (WMS). Warehouse spaces are premium today, so you might have to make the most of the space available. Smart warehouse technologies can do this for you. They can also automate tasks, reduce errors, and enhance supply chain efficiency.

- Now that you have a solution in hand, you have to choose your technology partner. Choose one who can provide you with customized solutions. Moreover, the product that you are purchasing has to be scalable.

- If you already have some logistics management software in place, check integration compatibility.

- The next part is the most important one. You have to calculate the upfront costs and compare them to long-term returns.

ROI in Logistics Automation

ROI or Return on Investment is a financial metric. It is a comparison of the total investment against the profit you gained from it.

You can calculate the ROI using this formula:

| (Profit – Investment)/ Investment |

For example, if your total profit is $100,000 and your total costs are $65,000, your ROI is ($100,000 – $65,000) / $65,000 = 0.53 (53%).

ROI can help you understand how profitable your investment will be. After all, the returns must outweigh the investment for you to have monetary gain.

Automated logistic systems are investment-heavy. Consequently, calculating its ROI can help you justify the investment. But there is a fact to consider here. The total returns from logistics automation are not quickly apparent. You might be able to calculate the reduction in labor costs. But these are not the only returns you get. So how do you calculate the potential ROI for logistic automation?

For this, you need to know which metrics to track and measure.

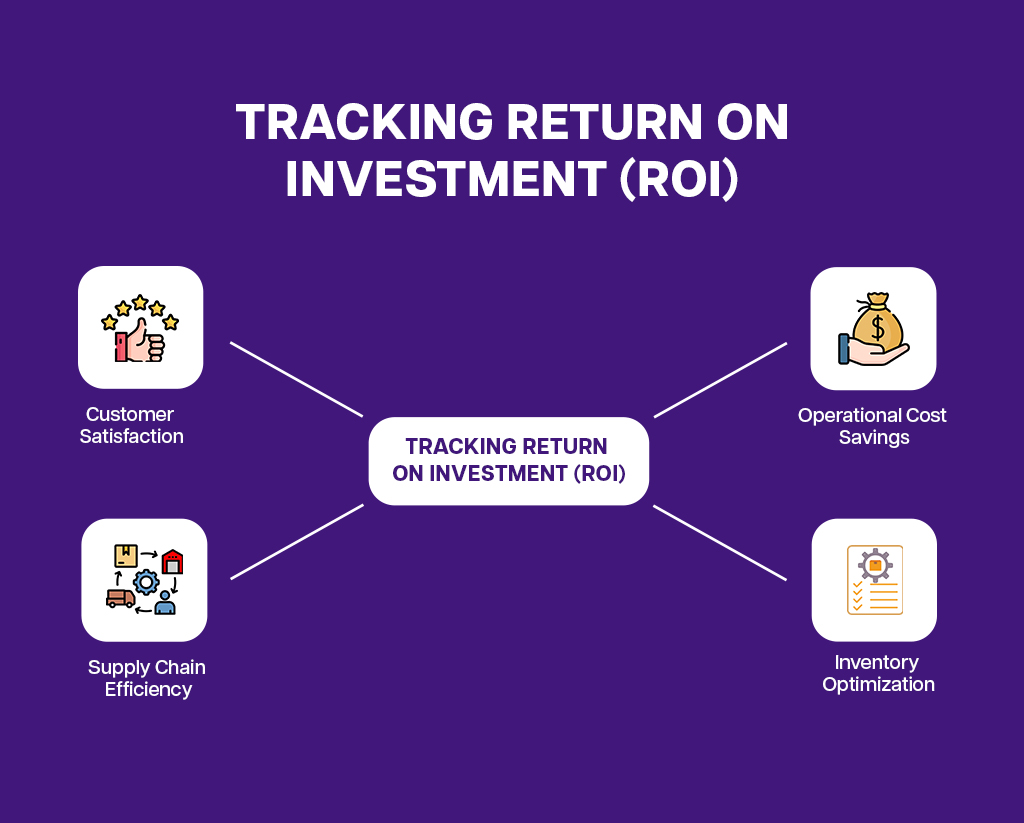

ROI Metrics to Track and Measure in Logistics Automation

1. Operational Cost Savings

This would be one of the easiest automation ROI metrics to track. Obviously, logistics automation can reduce manual labor and eliminate redundant processes. You have to calculate this cost reduction in logistics operations.

You can calculate operational cost reduction by comparing pre-automation and post-automation operational expenses. Be sure to include labor, fuel, and overhead costs when calculating.

2. Time Savings

Automation saves you a lot of time. And as they say, time is money. Automation in supply chain or order fulfillment automation can give you significant time savings.

You can measure this by comparing the time taken for key tasks before and after automation.

3. Inventory Optimization

Warehouse automation technologies can aid inventory optimization. By this, we are referring to a reduction in overstocking, understocking, and inventory errors. This will ultimately lead to cost savings and better cash flow management.

This metric will be easy enough to track and calculate. First, calculate the inventory holding costs before automation. Then, compare it to inventory holding costs after automation.

4. Supply Chain Efficiency

AI and robotics in logistics can positively impact supply chain efficiency. The automation will undoubtedly improve visibility and coordination. It will also reduce losses that could arise from delays and errors.

To calculate this metric compare the percentage of on-time deliveries, average transportation costs, and overall supply chain downtime before and after automation.

5. Customer Satisfaction

The logistics ROI measurement tools we mentioned till now were more or less tangible and measurable. However, customer satisfaction is much more difficult to calculate. Think of it this way: automation reduces errors and aids timely deliveries. Moreover, AI in logistics can enhance customer communication. This will in turn improve customer retention rates and build loyalty.

You can calculate this metric using customer retention rates, customer satisfaction scores (CSAT), or Net Promoter Scores (NPS).

As you are trying to track and measure the total ROI from logistics automation, remember to include all these metrics. This will help you determine if the savings across these areas justify the initial investment in automation.

Challenges and Solutions in Adopting Automation

Even if you are convinced by the potential ROI, automation still poses a couple of challenges. Let’s address each of them:

1. Inaccurate Data

Solution – All you need to do is improve data accuracy through regular audits. Also, implement data validation protocols and advanced data analytics tools.

2. Hesitance from Staff

Solution – Give them a clear understanding of the many benefits of automation. Let them know that it will reduce their workload. Also, offer training programs to help them upskill.

3. Integration Difficulties

Solution – You have to work with technology providers that offer scalable and customizable solutions. And before purchasing conduct a compatibility assessment.

Why Choose Fetche for Logistics Automation?

So far we have discussed the potential ROI, benefits, and solutions to the challenges of automation. Now we would like to introduce you to one logistics software where all these come together. We are talking about Fetche, an ERP that is scalable and customizable.

Let’s take a quick look at its features:

- As an ERP software, it integrates all aspects of a logistics business.

- It is highly customizable.

- Enhances visibility through supply chain automation.

- It combines multiple functions into one platform.

- It provides better integration and reduces errors.

- Centralizes data across various departments.

- It has an intuitive, user-friendly interface.

- It is scalable and can grow with your organization.

- Provides better long-term ROI.

- Advanced reporting and analytics.

- Automates cross-departmental workflows.

Compared to standalone automation software, an ERP like Fetche integrates all aspects of logistics operations. This includes shipment tracking, inventory management, accounting, and customer service. So by choosing it, you get more than just one kind of automation.

Conclusion

Automation has been leading the digital transformation in logistics. Logistics automation simplifies complex logistics processes, reduces errors, enhances supply chain efficiency, optimizes inventory, and reduces operational costs. Moreover, with automation, your ROI in logistics is bound to see a jump. While requiring a hefty initial investment, it still provides great value in the long run. So, is logistics automation truly worth it? The answer is yes. With the right logistics tools, your business is bound to reach new heights.