There was a day when mere shipment of products from point A to point B was an accomplishment—and, most times, the customer’s sole expectation. But now, the scenario is quite different. It’s not just about delivering the goods that are assigned to be delivered. But about how they are delivered— if it was done within schedule, without any holdups, on budget, and with end-to-end visibility. Even for that, these parameters might not suffice to ensure customer loyalty. This change requires the logistics sector to invest greater strategic energy and adopt automation to not only keep pace with increasing expectations but also minimize operational stress. In these circumstances, digitization is the strongest and easiest solution to all the mishaps—shuffling the processes, improving the satisfaction of customers, and eventually increasing return on investment (ROI).

The reason digital transformation in logistics is so critical today is that it can consolidate intricate operations into a single, smart system. From data-centralizing logistics software solutions that automate mundane tasks to ERP software linking procurement, inventory, and delivery on a single platform—technology is converting traditional logistics to smart logistics. The move not only increases accuracy and transparency but also releases human resources for strategy and innovation.

If this topic sparks an interest in you or might help your business in one way or another, read on to learn about how the digital transformation journey is reshaping the logistics sector.

Why Digital Transformation in Logistics is No Longer a Choice?

The logistics industry is perpetually under the gun—fuel prices, growing customer demands, global competition, labor shortages, and environmental issues. In this kind of convoluted landscape, it’s no longer an option to remain analog.

Logistics industry digitalization helps companies address these pressures along the way. Automating routine tasks, offering real-time information, and amplifying supply chain visibility help logistics companies react quicker to disruptions and deliver better to customers. Further, as global e-commerce increases and last-mile delivery becomes more complex, the necessity for agility is greater than ever. Firms that put off their digital transformation process stand to lose out in the AI in Logistics era.

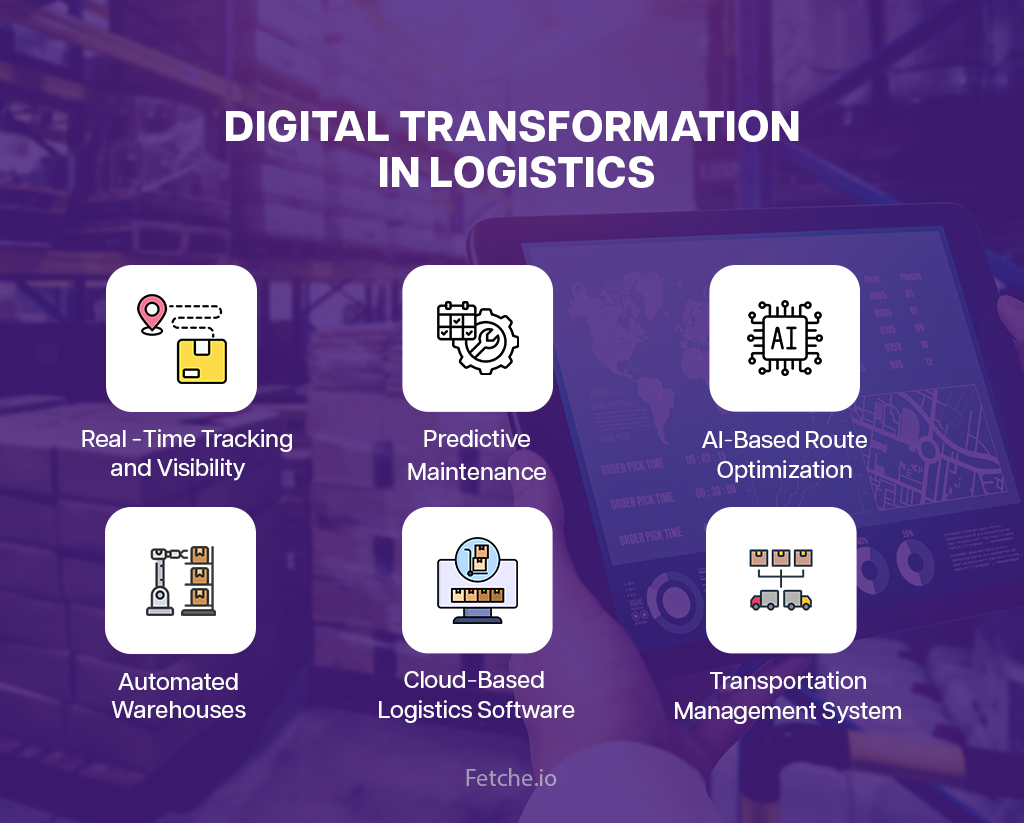

What Does Logistics Digital Transformation Look Like?

Let’s attempt to better understand what’s really going on on the ground by looking at some actual scenarios of how logistics automation is transforming the game:

1. Real-Time Tracking and Visibility

Customers increasingly want to know exactly where their parcel is in the moment, which is a fair demand to seek, as everything and anything is in transit via cargo these days. GPS and IoT integration in logistics enables real-time tracking of goods, vehicles, and containers, giving greater visibility and lessening the stress on the customer end. Less stress means more satisfaction; the more the satisfaction, the more the loyalty.

2. Predictive Maintenance

IoT in logistics enables truck and equipment sensors to alert before a problem becomes critical. This way, problems could be forecasted, and necessary measures could be taken beforehand. Predictive maintenance, thus, altogether lowers breakdowns, saves capital, and improves safety for fleets.

3. AI-Based Route Optimization

Artificial intelligence in logistics enables firms to forecast traffic flow, weather interference, and delivery timing to recommend ideal routes. And when such triggers are removed from the picture, on-time delivery becomes rather easier and more attainable and thus optimizes logistics efficiency and delivers products on schedule.

4. Automated Warehouses

Automating warehouses was one of the revolutionary changes that took over the industry by surprise, making warehousing tasks easier than ever. Cutting out errors, accelerating inventory control, and optimizing labor costs may not seem like a big deal, but they were the actual factors that changed the face of the industry. Things like barcode scanning, sorting machines, and automated forklifts are not a rare scene to see in warehouses anymore; rather, they are usual in advanced warehouses.

5. Cloud-Based Logistics Software

Having all your documents and operations under one single platform is a game-changer. This centralized logistics software solution provides teams with information anywhere. From tracking deliveries to processing customer orders, cloud platforms not only eliminate all kinds of departmental silos but also elevate the whole logistics process.

6. ERP Software Implementation for Integrated Operations

ERP software today integrates various business processes—from order management to billing and HR to procurement—on a single platform, facilitating seamless coordination and real-time decision-making.

7. Transportation Management System (TMS)

Transportation management systems (TMS) is a savior for logistics businesses as it helps with planning, executing, and maximizing logistics strategies effortlessly. It offers route automation planning, freight audit, and load optimization, which enhance cost savings and delivery precision, the prime ingredients of logistics.

8. Data Analytics for Demand Forecasting

Businesses today use historical data and industry data trends to better forecast demand. This minimizes overstocking, prevents stockouts, and provides lean supply chains that are responsive.

Benefits of Logistics Digital Transformation

Let us discuss how this digital transformation is changing results for both companies and clients:

- Digitization and automation rule out manual labor, lower errors, and accelerate business processes. This translates to enhanced logistics efficiency and a higher number of deliveries completed within lesser time frames.

- With real-time monitoring, quicker deliveries, and effortless communication, customer satisfaction goes through the roof. Digital solutions also simplify return handling and issue resolution.

- Route optimization, warehousing automation, and minimizing downtime through predictive maintenance bring big cost savings for logistics businesses.

- There is quicker decision-making with real-time access to information for managers. Bottlenecks are determined, while hidden opportunities are found using analytics software.

- Digital technologies power more sustainable behaviors like optimized routing, fuel tracking, and reduced paper consumption, which in turn allow businesses at large to keep up with their sustainability commitments.

- A well-equipped digital infrastructure helps businesses to scale quickly upwards or downwards with demand and be more vigilant in reacting to disruption in markets or global crises.

Top Logistics Challenges and Proven Solutions

Even with digital tools at hand, the path isn’t all milk and roses. Take a look at some of the key logistics challenges most companies struggle with—and ways to overcome them:

Legacy Systems and Fragmented Platforms

Challenge: Many firms still rely on outdated software and disjointed tools.

Solution: Migrate to unified platforms like logistics ERP solution and cloud-based logistics software solution that bring all operations under one roof.

Upright Resistance to Change

Challenge: Staff might resist new tools and processes.

Solution: Give sufficient training, emphasize the logistics software benefits, and engage users early in the process of transition.

Looming Cybersecurity Threats

Challenge: With more data online, security risks increase.

Solution: Implement robust cybersecurity protocols, regular audits, and secure data storage practices.

Data Overload and Poor Analytics

Challenge: Too much data might be perplexing if not treated correctly.

Solution: Utilize analytics and dashboards powered by AI in order to derive actionable insights and enable improved decisions.

Best Practices for a Successful Logistics Digital Transformation

Adopting digital logistics best practices can ease the transition and maximize ROI:

1. Begin with a Clear-cut Strategy: Pinpoint what you want to achieve by a specific time. Clarity allows you to pick the appropriate tools to achieve it.

2. Engage All Stakeholders: From drivers to warehouse personnel to managers, bring all of them on board the planning process. Their input can identify genuine problems and enhance adoption.

3. Prioritize Data Integration: Have all systems—TMS, WMS, ERP software, CRM—all integrated so there is no interruption in data flow. This gives you a single source of truth.

4. Embrace Modular Technology: Use solutions where you have the ability to scale and be flexible. Modular systems enable you to implement technology at your own speed without huge initial investments.

5. Focus on User Experience: Complicated systems have lower user adoption. Use a simple, easily accessible, easy-to-use system that requires the bare minimum training to navigate through.

6. Monitor, Measure, Optimize: Utilize KPIs to monitor progress, such as delivery times, fuel consumption, or customer satisfaction, and modify your digital transformation roadmap in response.

Measuring the Effect of Digital Transformation in Logistics Expansion

Only when we begin to measure its long-term effect does the real worth of digital transformation in logistics reveal itself. Firms that adopt technology early will realize improved margins, reduced operating expenses, and improved customer retention. Measures such as delivery accuracy, warehouse turnaround time, fuel efficiency, and customer complaints provide concrete evidence of success. More significantly, digital preparedness renders companies resilient against disruptions in the global market, allowing them to learn quickly and stay competitive. In short, the digital leap and AI in logistics not only simplify operations but also facilitate sustainable growth.

Conclusion: How to Get Started with Digital Transformation

The logistics world is undergoing transformation, and you may be easily left behind if you take action late. Small business or a traditional freight firm, it’s time for some smart logistics. Go small but think big. Start with automating repetitive tasks and introducing intelligent tracking systems. Invest incrementally in a single-source centralized ERP for logistics to integrate your warehouse, transport, finance, and customer service functions into one. By adopting the right logistics software and taking calculated steps, you’re not just upgrading your systems—you’re future-proofing your business as well as adding to the future of logistics technology.